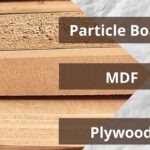

Plywood is one of the most versatile and widely used building materials in construction, furniture making, and various other applications. It is an engineered wood product made from thin layers of wood veneer, known as plies or plies, glued together with high-quality adhesives. However, not all plywood is created equal. Different grades of plywood are available in the market, and they significantly impact the quality and performance of the final product. Understanding these grades is essential for making informed decisions about which plywood is best suited for specific projects.

**1. ** Grades of Plywood

Plywood is classified into several grades based on its quality, appearance, and intended use. The most common grading systems include A, B, C, and D, with each grade having subcategories to provide more detailed specifications. Here’s a brief overview of the standard grading system:

- A Grade: This is the highest-quality plywood grade, with the best appearance and minimal defects. It has a smooth and knot-free surface, making it suitable for projects where the plywood will be visible, such as cabinets, furniture, and interior decor. A-grade plywood may also have a face and back designation (A-A) for applications requiring both sides to have a premium finish.

- B Grade: Plywood in this grade is slightly less aesthetically pleasing than A grade but still of high quality. It may have minor defects, such as small knots, discoloration, or patches. B-grade plywood is commonly used in applications where one side of the plywood will be visible, and the other side may be hidden, such as wall paneling or underlayment.

- C Grade: Plywood in this grade has more noticeable defects and imperfections, including larger knots, patches, and blemishes. It is often used for structural purposes, where appearance is not a primary concern, such as roofing, sheathing, and subfloors.

- D Grade: This is the lowest-grade plywood, featuring numerous defects, knots, and splits. D-grade plywood is mainly used for temporary structures, concrete forms, and other applications where appearance and long-term durability are not significant factors.

**2. ** Impact on Quality and Performance

The grade of plywood directly affects its quality, strength, and overall performance in various applications. Here’s how the different grades impact the plywood’s characteristics:

- Strength: A-grade plywood, with its smooth and consistent surface, tends to be stronger and more durable than lower grades. It has fewer voids and gaps between plies, providing better structural integrity.

- Appearance: A-grade plywood is preferred for projects where aesthetics matter, as it offers a pleasing, knot-free surface suitable for staining or clear finishes. On the other hand, lower-grade plywood may require painting or covering with veneer or laminate to improve its appearance.

- Cost: Higher-grade plywood, especially A-grade, typically commands a higher price due to its superior quality and appearance. Lower-grade plywood is more budget-friendly but may require additional work or finishing to meet specific project requirements.

- Suitability for Applications: Different grades of plywood are designed for specific uses. A-grade plywood is ideal for visible surfaces and premium applications, while C and D grades are commonly used for structural purposes and hidden elements.

**3. ** Choosing the Right Grade

Selecting the appropriate grade of plywood depends on the project’s requirements, budget, and intended use. Consider the following factors when making your decision:

- Application: Determine whether the plywood will be visible or concealed, and whether it needs to withstand heavy loads or external elements.

- Aesthetics: If appearance is crucial, opt for higher-grade plywood with a smooth, unblemished surface.

- Budget: Balance the quality and cost to find plywood that meets your needs without exceeding your budget.

- Environment: For outdoor or moisture-prone applications, consider marine-grade plywood, specially treated to resist water damage.

In conclusion, understanding the different grades of plywood is essential for making informed choices when starting a construction or woodworking project. The grade directly impacts the quality, strength, appearance, and suitability of the plywood for various applications. By selecting the right grade, you can ensure that your project is not only aesthetically pleasing but also structurally sound and durable.